Ad: I’m doing an ACT for Chronic Pain webinar (4 sessions) in January 2012. Email me at polkkev@gmail.com for more details.

Background: I started off to be an Industrial Organizational Psychologist and ended up a Clinical Psychologist who thinks a lot about how mental health delivery services are organized. In recent years I’ve learned a lot about Lean Management that’s based on the Toyota model. It turns out that ACT and Lean are similar.

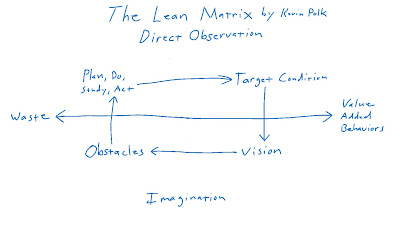

The Diagram: Recall that ACT emphasizes getting out of your head and into your life. Lean talks about this in terms of getting out of the world of Imaginary problems and solutions and into the world of direct observations and solutions.

We’ve all done this in meetings…We sit around and someone says, “But what if this happens?” Then we all talk for an hour about how to fix that imaginary problem. Once that’s done, then someone says, “But what if this happens?” Then we talk for an hour about how to fix that imaginary problem. Once that’s done, then…

Fixing imaginary problems is a horrible management trap and Lean emphasizes getting out of that trap and into direct observation. In a factory that means getting down on the shop floor and watching. In a hospital that means watching a patient, a health care worker, or both. Direct Observation rules.

In the world of Direct Observations you ‘see’ two types of behaviors:

- Value Added

- Waste

Of course there is a place for Imagination, and that comes in terms of Vision and dreaming up ways to move toward that Vision called Target Conditions. However, too much talk becomes and Obstacle. You see those at the bottom of the diagram in the “mental experiencing” section of the Matrix.

After a bit of talking about Vision and the Target Condition, the Obstacle of talking too much arrives and it’s time for Plan, Do, Study, Act (PDSA) cycles. Notice that the Target Condition is to the right of PDSAs. The PDSAs are designed to move toward the Target Condition. This is the world of direct observation. The Plan is concrete behaviors. People Do the concrete behaviors. Direct Observation of the results of the behaviors are Studied in terms of waste and value added. Then people take new Action based on the results. Multiple PDSAs are done until the Target Condition is reached.

Once the Target Condition is reached, then it’s time to line things up with the Vision again.

I think of this as organized evolutionary process.

The Lean way is lots of fun once you get it implemented.

Reference: Toyota Kata by Mike Rother

Leave a Reply